Aluminium VS Polycarbonate Serial Number Label

At GSM Online Label Sales, we often encounter similar questions from our customers and a prime example of these are;

• For serialised number labels, which is better aluminium or polycarbonate?

• Do I need aluminium or polycarbonate for my serial number plates?

• If I need self-adhesive serial number labels what material is best?

To help to answer all these questions we will explore the benefits of both aluminium and polycarbonate serial number labels and this may help to decide which may be best for your application.

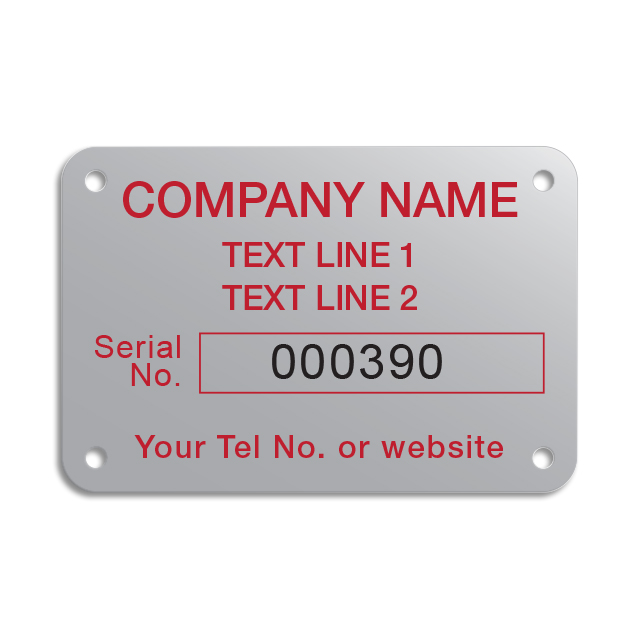

Both aluminium and polycarbonate serial number labels are printed using a digital printer to print the variable information. At GSM Online Label Sales, our digital suite houses a specialist printer that can print into the pores of the anodised aluminium. Our other printer can reverse print onto the polycarbonate. Therefore, both materials are suitable as serialised labels.

Whether you chose aluminium or polycarbonate for your labels depends upon your application. Both options are durable enough to be used outdoors as they have layers protecting the ink. The plastic (polycarbonate) option is thinner and therefore would benefit a surface application however the aluminium is 1 mm thick and would be a good option to be fitted into a recess. Which option would work best for you is dependent upon your application.

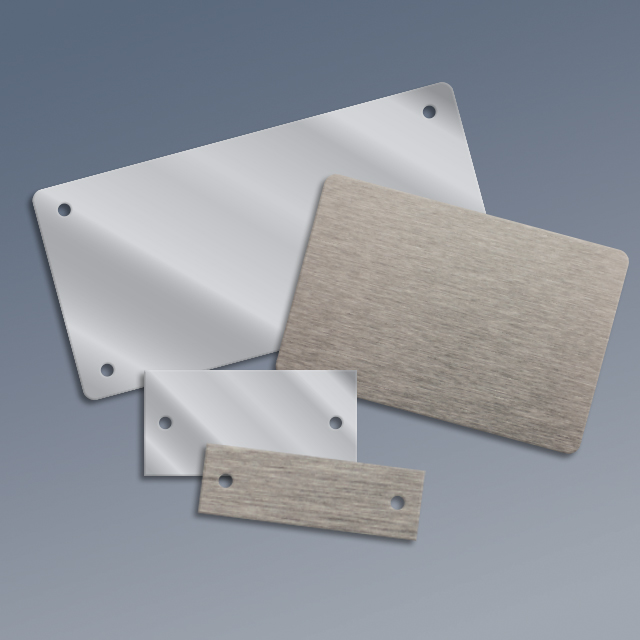

The polycarbonate labels are supplied only as self-adhesive however the aluminium labels can be supplied with either fixing holes or adhesive. This is because the aluminium can house fixing holes better than the polycarbonate due to the thickness of the materials used. Again, the best option for your application is dependent on the specification.

Both options are durable and hard wearing but the nature of your requirement will help determine the best option. To discuss your specification further call us or to order, click here.