How to mark your labels?

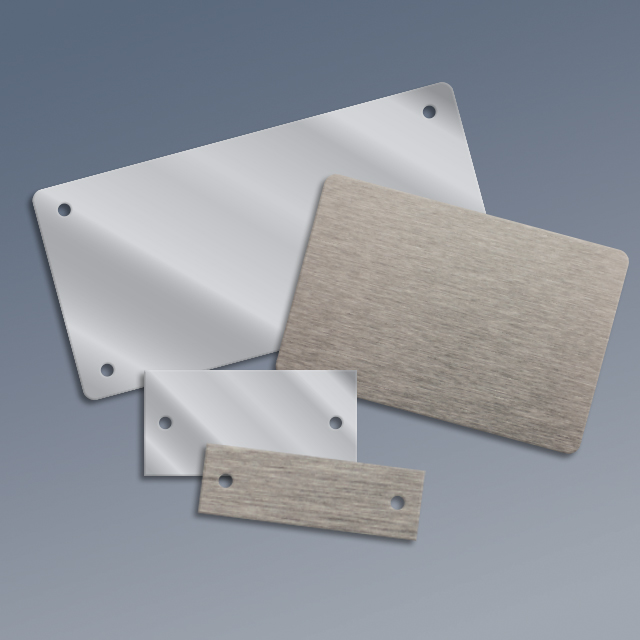

GSM Online Label Sales offers a range of blank metal labels for in-house marking but once we have supplied the blanks, how should you mark them?

It is of course down to preference but there is several ways to create permanent markings onto plates including; engraving, dot peen marking and laser marking.

The laser marking process super heats the surface of aluminium or stainless steel blanks to evaporate a tiny bit of the surface. On a natural piece of metal this would leave a contrasting effect however if we take aluminium, flood with a colour and then seal it, when we laser mark the aluminium it produces a lighter contrasting detail to the coloured metal plate.

Dot peen marking is useful for marking with serial numbers and is also known as micro-percussion and indent marking. Dot peening is a series of ‘dots’ that are punched close together in a pattern to produce text or numbers. The machines used are programmed systems that make error free and permanent marks in metals such as aluminium and stainless steel.

Engraving is the process of cutting grooves into the surface of the metal. This process leaves the detail cut into the material. Contrast can be improved by infilling with paint or wax.

As stated it is preference as to which method you use for your in-house marking requirements but if you require any further details on the machinery suitable please contact our sales team or alternatively click here to view our full range of blank metal labels.