How you can mark a blank label

When it comes to marking the detail onto a blank label there are a few options as to how you can achieve different finishes.

Hand Stamping

It is possible to mark both aluminium and stainless steel blank labels using a hand stamp. Hand stamps are ideal for smaller volume labels where characters may be varying. As long as not too much detail is required it can be an ideal solution to marking. However, your application can be timely and therefore restricts on how many may be produced. Hand stamping would also make it difficult to complete the marking on-site as it can be a little fiddly. But for use as low volume in-house marking equipment it is ideal.

Laser Marking Equipment Options

Laser marking a blank label can achieve some very complex detail. The laser marks the surface of the metal to create detail. This equipment is ideal for creating logos and can achieve intricate artworks. A laser marker can also create serialised numbers on the plates where each number is different to make each plate individual. Depending on the level of detail required to be laser marked onto the plate will dictate how long it will take to print and therefore how efficient it is to laser mark all of the detail.

Engraving Equipment

One of the old favourites for marking is an engraver. Although, one of the more traditional pieces of equipment to mark detail onto a metal label it is still used widely across companies. Engraving generally penetrates the metal harder and therefore provides a very obvious indent for the detail that is required. It may not be the newest, state of the art and digitalised machinery but it still does the job and marks the metal.

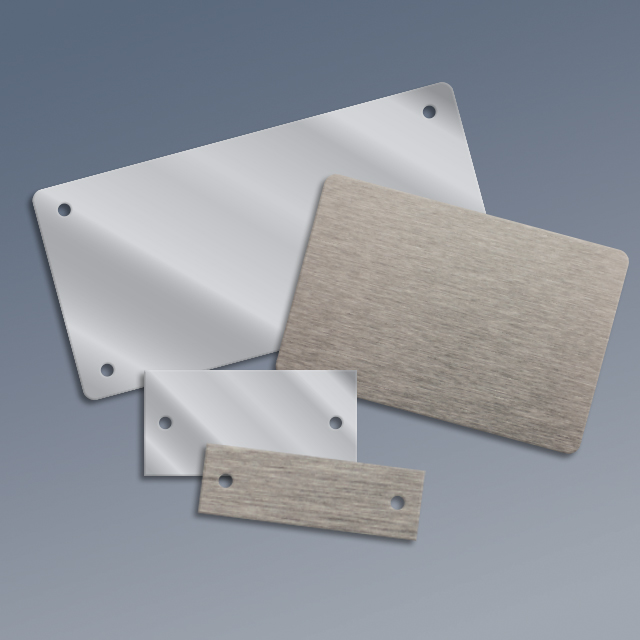

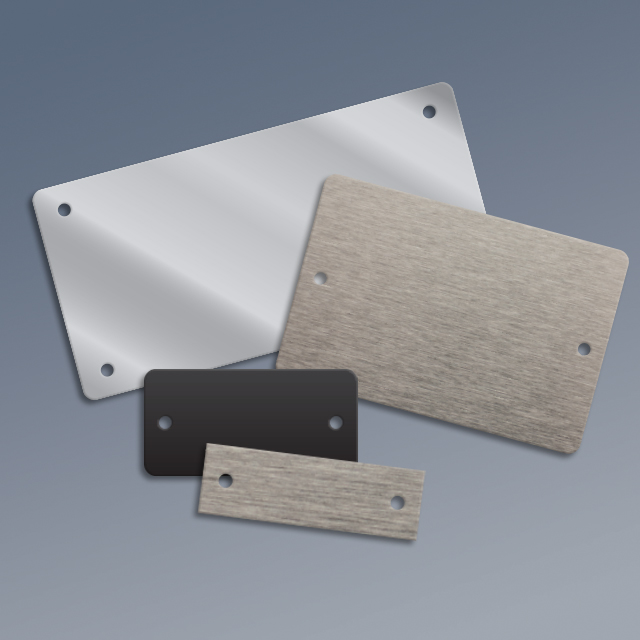

View our range of blank labels that can be used with these pieces of machinery and add either fixing holes or adhesive to attach them to your product.