Why Metal Asset Tags should be used in your Industry

When tracking assets it is important to have a securely fixed and unique identifying numbered metal asset tag so your assets are easy to trace back to inventory, whatever your industry.

What makes the asset tags so durable?

At GSM Online Label Sales we use anodised aluminium when manufacturing metal asset tags. Anodising aluminium is the process of electrically charging the aluminium which opens the pores of the metal. Ink can then be printed into these pores before being sealed beneath the anodic layer to create a hard-wearing and durable label. This makes the labels resistant to weathering, scratching and general wearing.

These asset tags are therefore great for use outdoors on items such as fitness equipment, outdoor furniture and vehicles.

How to affix to products

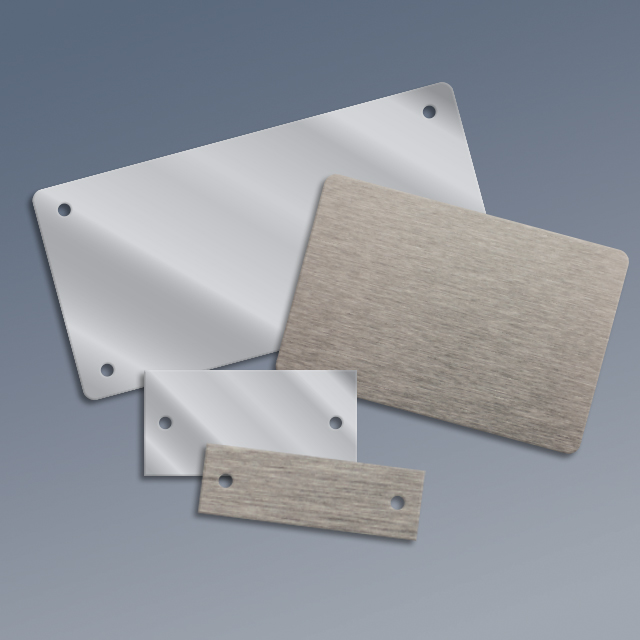

We use 1mm thick aluminium that can include either 3M 468 adhesive and/or pre-drilled fixing holes. Using adhesive offers a quick and easy way to apply the label and will stick to most surfaces (if applied correctly).

The option of including pre-drilled fixing holes is ideal for when a plate needs to be located in a very specific location or in an extremely industrial location.

What information to include on the tag

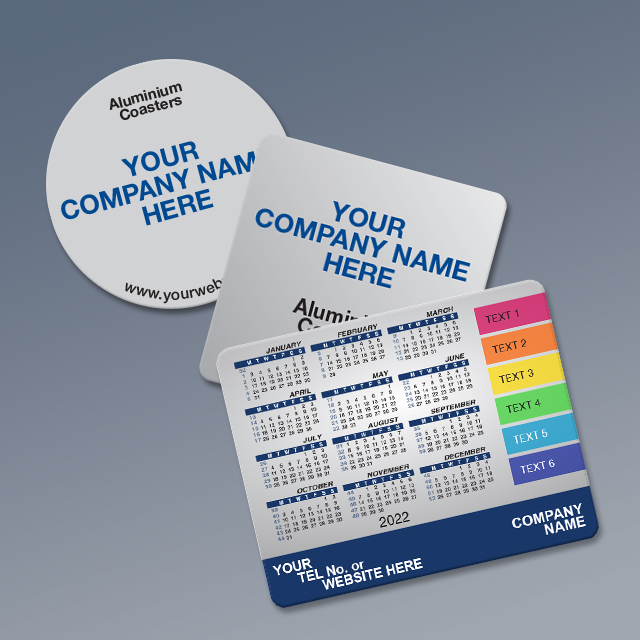

Our standard asset tags include; your company name, a sequential number and your telephone number or website address. Our larger sized plates allow space for more details to be included such as; your website address and additional text. All are customised to include your company details.

Order Today

View our metal asset tag options available and then simply make the selections you wish and advise of what text you require printing.

If you want an asset label that is more flexible yet still durable enough for use outdoors and is also scratch-resistant we can also offer a polycarbonate under-surface printed asset tag. Find out more about these here.